Build Your Own Easy To Print 3D Printed DIY Electric Car

No, this isn’t a toy, and it’s not an April Fools joke. This is a non-commercial 3D printed full-size car made with a hobby printer. Plans include how to make the body and components for a one-person car powered by an electric motor, with a full suspension, brakes, and steering.

What materials are necessary for the 3D print car?

Licensed as an International Attribution Sharealike (CC-by-sa 4.0), it can be copied, changed, and built upon for any purpose, even commercially. Put simply, all you need is a standard FDM 3D printer and a bunch of either PLA or PETG plastic. You’ll also need a few off-the-shelf parts, and may need to print some of the parts with Nylon/Polyamide (PA) plastic.

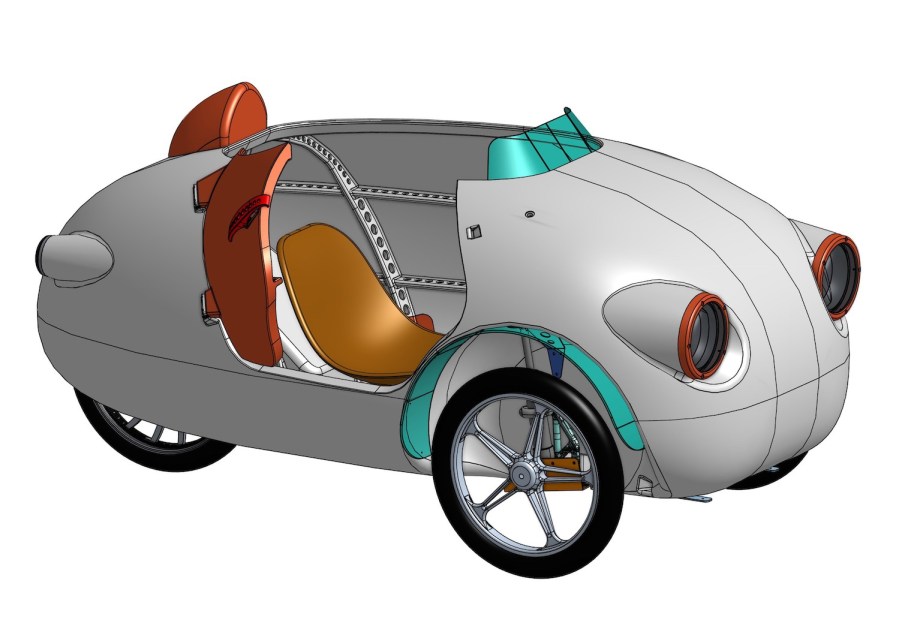

The plans for the Jellybean 3D Printed Car were conceived by Gonzalo Chomon, as published on Hackaday. Since a hobby printer can’t make large panels like the body, his plans call for smaller printable pieces that are then interlocked and glued or plastic welded together. You can see how they are assembled in the illustrations.

“We will enjoy and learn through the process”

His challenge was to test the limits of 3D printing components. “This project does not aim to reproduce a standard vehicle construction,” he says. “Many things can go wrong, but we will enjoy and learn through the process.”

He wanted the Jellybean to be printed from PLA or PETG plastic because it is easy to find and easy to print. Trying to print larger components with ASB, PA, or PC plastics is hard for a hobby printer. They also warp fairly easily.

Has the 3D print car been tested?

The Jellybean utilizes a unibody construction as there is no frame. As you can imagine, strength was of the utmost importance, and Chomon spent lots of time testing for various stresses to come up with the lightest, yet strongest components possible. And being able to easily 3D print them was mandatory.

With 3D printing, inner honeycomb structures inside of parts offer extremely strong parts that are also lightweight. Gluing smaller printed pieces together creates larger parts. He also formulated his own chemical welding system. The easy-to-follow instructions for the mixing of the bonding material are the subject of one of several YouTube videos.

What about hardware?

You can get easy-to-find components and materials online or at hardware stores. Things like the bicycle wheels and tires, hinges, headlights, Heim ends for the steering, etc, are all off-the-shelf parts available online or at better-stocked hardware stores. A parts list is part of the plans.

The same goes for the charger. For the battery, Chomon shows how he is making it from hundreds of small batteries linked as Tesla does its car batteries. Or any 48-volt e-bike battery will also work. The inwheel motor can be between 1,000 and 2,000 watts and is also easy to source.

Is it goofy looking? Yes. Does it matter? No. Can you drive it from Cleveland to Cincinnati? Of course not. But if you’re into projects that actually do something, and love all things motorized, it looks like a great project. And it might even get you thinking about trying to engineer your own electric parts-printed car yourself.

RELATED: Can You 3D Print Your Own Rocket? Relativity Space Does!

Related post url: