Could This Paste Make Hydrogen Fuel Cell Cars More Practical?

As more automakers double-down on an EV future, it’s clear that improving battery technology is a major goal. However, at least a few automakers, including Toyota and Hyundai, are still banking on powering electric cars with hydrogen fuel cells. That’s despite the fact that, at least in the US, hydrogen-powered EVs don’t have a significant market presence. But a new development from a German research institute may help change that.

Why have electric cars with hydrogen fuel cells failed to catch on?

As with many battery-powered electric vehicles, hydrogen fuel cell cars struggle with supporting infrastructure. Basically, unless you live in California, there aren’t really any hydrogen fueling stations. But hydrogen EVs face another issue: storage.

Producing hydrogen, whether through water electrolysis or some other process, can be done on-site, Car and Driver reports. And it’s potentially a more energy-dense storage medium than lithium-ion batteries, Autoweek reports. However, once it’s made, it has to be compressed into a liquid or high-pressure gas for storage, transportation, and use, Chemistry World explains. This creates several drawbacks.

Firstly, compressing hydrogen for use in fuel-cell cars requires significant amounts of energy, which also raises the price. Secondly, you need special high-pressure tanks to store it, which are often expensive and somewhat heavy, the US Office of Energy Efficiency & Renewable Energy reports. Though to be fair, a battery-powered EV with a hydrogen fuel-cell car’s range would be heavier still, Autoweek reports. And, like with EV battery packs, simply putting in a larger tank would lower the hydrogen car’s efficiency and range, requiring a larger tank…you get the point.

Fraunhofer Institute’s ‘PowerPaste’ may resolve the storage issue for hydrogen cars

This is where Germany’s Fraunhofer Institute for Manufacturing Technology and Advanced Materials comes in. The research institute recently announced the creation of a ‘PowerPaste’ that, on paper, addresses the hydrogen storage problem, Autoblog reports.

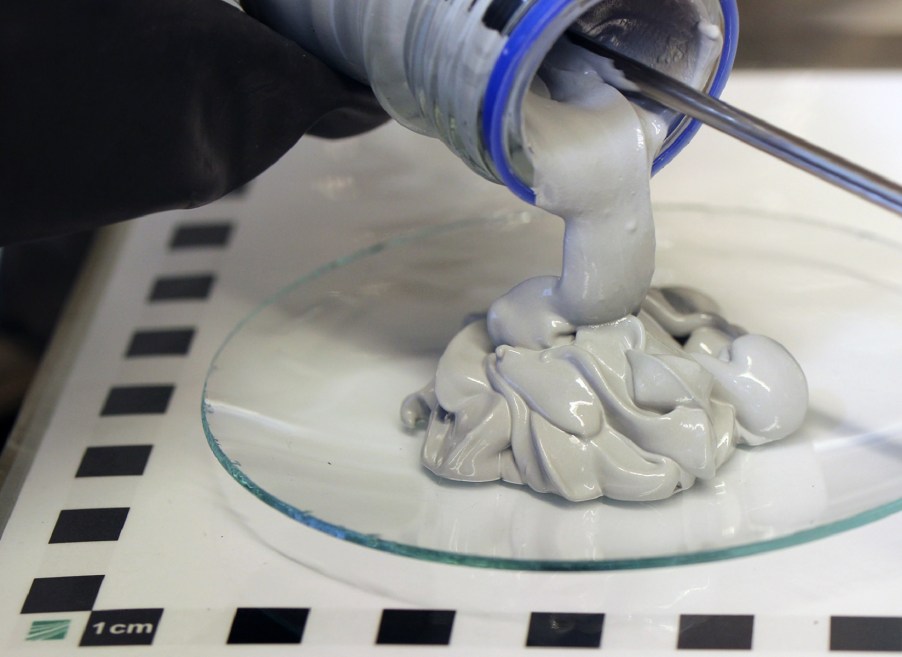

This PowerPaste is made of magnesium hydride and several stabilizing compounds, Popular Mechanics reports. And reportedly, it’s 10 times as energy-dense as a lithium-ion battery. It’s stored in a dedicated cartridge equipped with a metal plunger, and connected to a separate water tank.

Whenever the fuel-cell car or other vehicle needs power, the plunger squeezes the paste out of the cartridge. There it mixes with water from the tank; the magnesium hydride and water react to create magnesium hydroxide and hydrogen gas. Once that happens, the hydrogen travels to the fuel cell to make electricity.

One of the benefits hydrogen fuel-cell electric cars enjoy over battery-powered ones is refueling/recharging time. While even a fast-charging battery-powered EV takes about 30 minutes to recharge, refueling a hydrogen-powered EV takes maybe 10 minutes, Road & Track reports. And the Fraunhofer Institute claims its system should be similarly speedy: just replace the spent cartridge and refill the tank with water.

Will this paste actually see full-scale production?

The Fraunhofer Institute initially designed its PowerPaste system with e-scooters and electric motorcycles in mind. And it plans to begin running its pilot plant later in 2021 with a 4-ton annual production target, CE Energy News reports.

The Fraunhofer Institute claims it can adapt the PowerPaste system for cars. It all depends on how the initial testing goes. However, it’s worth pointing out that since 2019 the Fraunhofer Institute has been part of a government-sponsored program designed to improve German automakers’ battery “know-how,” Automotive News reports. So, it’s possible this ‘grey goo’ could reach the automotive industry sooner than we think.

That could mean hydrogen-powered electric cars could find their second wind.

Follow more updates from MotorBiscuit on our Facebook page.