Do Inline Six-Cylinder (I6) Engines Make More Torque?

There’s a common myth that an inline six-cylinder engine makes more torque than a similar V6 engine–or even a V8 engine. The myth seems to hold that engine torque is somehow a product of mainshaft length. But it’s entirely untrue. Inline engines do–however–have some key strengths over V6s and V8s, which are fueling this configuration’s dramatic comeback.

Do inline six-cylinder engines make more torque?

Torque is the product of an engine’s displacement, RPM, and the length of the piston’s travel (stroke). And while some configurations can rev to higher RPMs, there is no cylinder configuration that instantly grants an engine more torque. Yet somehow, the myth that inline engines have more torque seems to persist.

An engine with larger cylinders and a longer piston travel will make more torque than a similar engine with less displacement and a shorter stroke. The second engine may be able to rev to a higher RPM and make more horsepower. But the first engine will probably produce more torque.

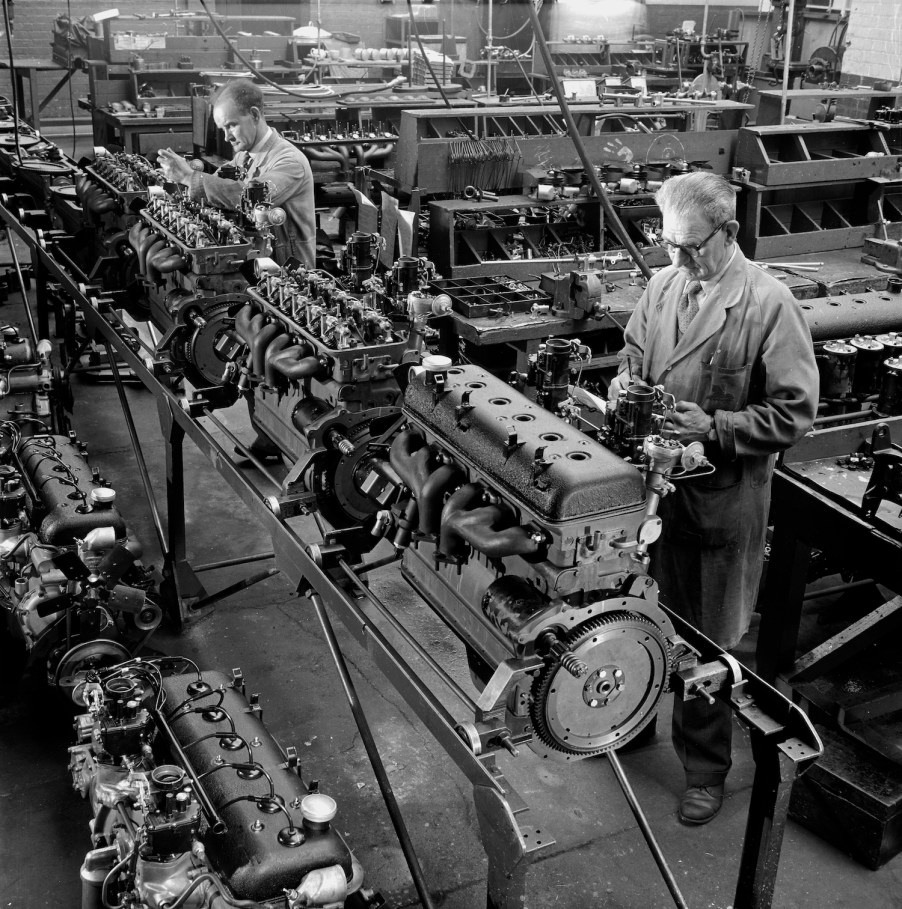

In decades past, many truck and automobile manufacturers offered a “straight-six” I6 engine as their entry-level engine. These engines, such as the legendary Mopar slant-six, or any of a number of even older I6s have earned a certain cult following. This is because they have fewer moving parts than a V-shaped engine, are often easier to access and thus work on, and often make loads of torque. But the torque of these I6 engines was a product of their long stroke, not their layout.

The layout of early I6 engines did allow a longer stroke. These engines, with just one cylinder bank, often had a taller cylinder bank than you’d find in a V6 or V8. In addition, an I6 is inherently harmonically balanced. This means that they vibrated less at high RPMs than their contemporary V-shaped engines.

What are the benefits of inline six-cylinder engines?

Inline six-cylinder engines are naturally balanced, vibrating less at high RPM. The ease with which exhaust can exit their cylinders helps RPM too. They also have fewer moving parts than v-shaped engines–thus costing less and breaking less often. Inline engines leave lots of space in the engine bay for speed equipment such as turbochargers.

Inline six-cylinder engines do have downsides. Because they are much longer than V6 engines they cannot be mounted sideways in a FWD car. Because automakers prefer using one engine for multiple vehicles, few modern automakers designed a standalone I6 for their RWD vehicles–until now.

The inline six-cylinder engine’s comeback

As automakers perfect pulling big power from small engines, inline six-cylinder engines are making a comeback. But this time, they aren’t V6 competitors–they are replacing the V8–according to Cars Guide.

The inline six-cylinder engine is on its way to becoming the powerplant of choice for front engine RWD sports cars. BMW, Toyota, Mazda, and Mercedes all either offer an I6 or will soon.

In addition, both Ram and General Motors kept the I6 alive as a turbocharged diesel truck engine. But now it looks likely Ram will swap its V8s for Stellantis’ new 3.0-liter twin-turbocharged “Hurricane” I6 gasoline engine. The first vehicle to offer the Hurricane will be the Jeep-built Wagoneer and Grand Wagoneer. Next, see Stellantis’ Hurricane I6 by the numbers or see the differences between I6 and V6 explained in the video below: