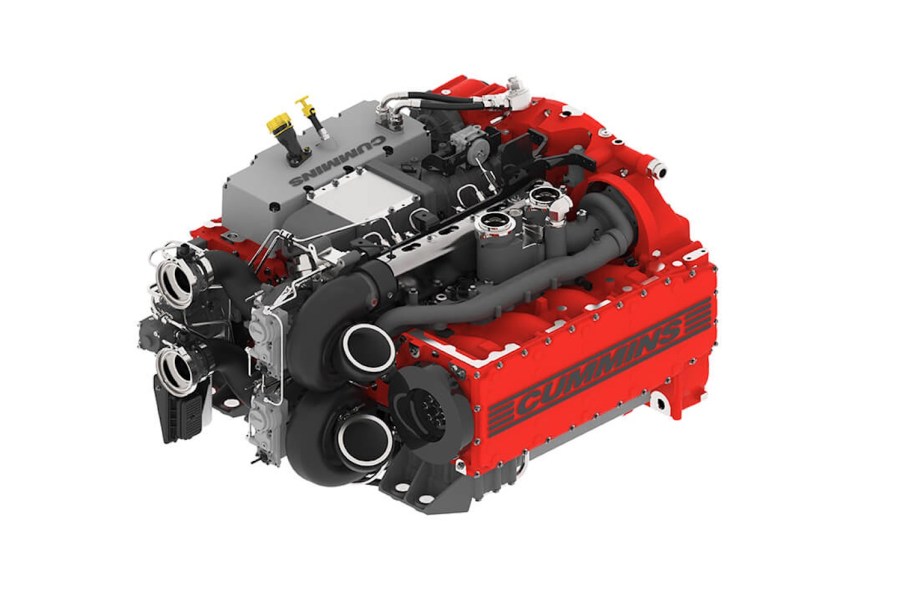

Meet ACE: A 1,000-Horsepower Cummins Diesel Engine With Turbochargers, a Supercharger, and Only 4 Cylinders!

Military engines are built differently than the powerplants available to us civilians. It is critical that both gas and diesel military engines have maximum output and reliability and, in some cases, a minimum footprint. But military technicians are comfortably swapping and rebuilding these engines whenever necessary. As a result, some of these engines are so “turned up” that their lifespan is measured in hours. So you may not be shocked to hear that Cummins is building a 1,000-horsepower “Advanced Combat Engine” (ACE) for the next generation of Army tanks. But you will probably be surprised to find out it has a supercharger, turbocharger, and only four cylinders. Why? Because the ACE leverages a distinct design with two pistons in each cylinder.

Opposed piston engines are a military tradition

Opposed piston engines, just like their name would suggest, have two pistons in each cylinder. These pistons are connected to separate crankshafts and travel towards one another to create compression.

On paper, the opposed piston layout is ingenious. You can create twice as much compression with half as much piston travel. No heat or other energy from the combustion process escapes into the engine’s head because the engine has no head. And in tight spaces, you can create twice as much displacement as a more traditional engine would.

In practice, opposed-piston engines present several significant engineering challenges. Their intake and exhaust valves are often just holes in the cylinder wall, so they must be a two-stroke. Without valves, it can be difficult to modulate airflow both into and out of the cylinders. In addition, they have two crankshafts, which must be geared together. As a result, this technology has been limited to very large engines in the past. You can learn more about how opposed piston engines work in the video below:

But militaries have still found uses for opposed piston engines, whether the Junkers Jumo 205 gasoline version used in German airplanes or the diesel engines that powered many U.S. submarines in the 40s and 50s. And thanks to Cummins, the military may soon use tanks powered by a small, modern opposed-piston diesel.

Cummins won the Army’s Advanced Combat Engine (ACE) contract, with a little help

The Bradly fighting vehicle and M109A7 Howitzer leverage a 14.8-liter, 750-horsepower Cummins turbodiesel V8. In fact, Cummins proudly advertises that its diesel combat engines power more tracked military vehicles than any other brand. But when the Army began to engineer its next generation of armored vehicles, it realized it would need a dramatically different engine.

The military wanted at least 1,000 horsepower for its new vehicle. But space inside an armored vehicle is critical. Pushing a V8 past 15-liters would cut into the passengers’ space. Cummins had the production capabilities to build the new engine but would need a partner to help design it.

Enter Achates Power (pronounced Ah-kay-tees). Since 2014, this startup has designed opposed-piston engines that leverage 21st-century technology and meet modern emissions standards. Cummins and Achates partnered up and designed an all-new opposed-piston diesel, which immediately won the Army’s Advanced Combat Engine contract.

The Cummins/Achates ACE is one mightly little engine

The ACE by Cummins/Achates is a horizontal inline four-cylinder with eight opposed pistons. It is less than four feet wide, four feet long, and under two feet tall. But don’t let this 1,000-horsepower diesel’s small size fool you: it weighs in at 3,500 pounds.

Achates has had to get creative to control airflow into an engine with no intake valves. One solution the company has developed is running a carefully tuned pair of turbochargers, and a supercharger. The ACE uses this same layout.

Next, read about the history of Cummins and the Russian Army or read more about the Cummins Advanced Combat Engine in the video below: