Save Your MKIII Toyota Supra From Head Gasket Failure With One Simple Fix

The MKIII Toyota Supra is a legendary sports car that has captivated automotive enthusiasts for decades. Unfortunately, however, it is very susceptible to head gasket issues. Fortunately, a simple fix can help you avoid this costly and time-consuming repair. In this article, we will explore the causes of head gasket failure in the MKIII Supra and provide an effective solution to save your beloved car from this predicament.

What is head gasket failure?

The head gasket plays a critical role in the engine’s proper functioning by sealing the combustion chambers and preventing coolant and oil from mixing. However, the head gasket can deteriorate over time due to various factors. Issues like engine overheating, insufficient maintenance, or wear and tear will create a failure point. When a head gasket fails, it can lead to severe consequences, including loss of power, overheating, coolant leakage, and potential engine damage.

MKIII Toyota Supra Head Gasket Problems

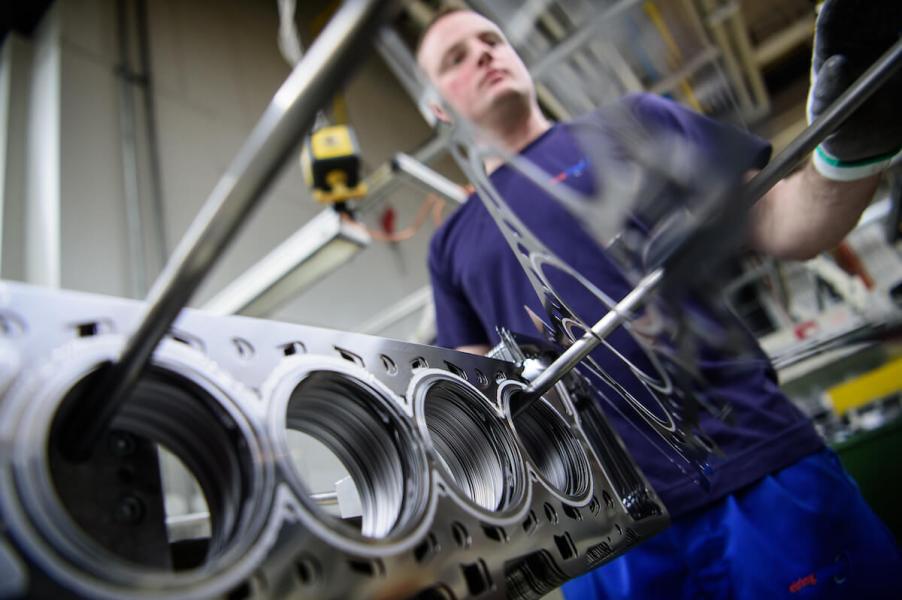

The MKIII Toyota Supra, particularly the 7M-GTE engine variant, is extremely susceptible to head gasket failure. This issue primarily arises due to the design of the factory head bolts and the engine’s aluminum construction. Initially, the head bolts are torqued incorrectly from the factory. However, if your head bolts have not stretched, you can re-torque them to the proper setting to save you some money.

However, the combination of high-performance driving, increased cylinder pressures, and engine aging can cause the head bolts to stretch and lose their clamping force. This results in a compromised seal between the head gasket and the engine block. A telltale sign of a failing head gasket is the engine overheating and leaking coolant down the side of the block.

Solve head gasket issues with an ARP head stud kit

Fortunately, there is a simple yet highly effective solution to prevent head gasket failure in the MKIII Toyota Supra. Installing an ARP (Automotive Racing Products) Head Stud Kit can significantly enhance the clamping force and overall strength of the head gasket assembly. The ARP Head Stud Kit replaces the factory head bolts with high-quality studs, washers, and nuts that provide superior clamping force, ensuring a secure and reliable seal. The ARP Head Stud Kit offers several benefits:

Increasing clamping force: The ARP studs will withstand higher stress levels than the factory head bolts. This helps prevent the head gasket from losing its seal under extreme conditions.

Enhancing durability: The MKIII Toyota Supra studs contain premium materials, such as ARP2000 or Custom Age 625+. The materials ensure exceptional strength and resistance to stretching or fatigue.

Easy installation: Each ARP Head Stud Kit is specific for the vehicle, making the installation process straightforward. However, professional installation is always ideal to achieve the best results.

Cost-effective solution: An ARP Head Stud Kit may seem like an additional expense. However, it is a small price compared to the potentially catastrophic consequences of head gasket failure. You can save yourself from expensive engine repairs by proactively preventing this issue.

Should you replace your head studs?

The MKIII Toyota Supra is an iconic sports car that deserves to be preserved and enjoyed for years. By addressing the common issue of head gasket failure by installing an ARP Head Stud Kit, you can ensure the longevity and reliability of your beloved vehicle. With increased clamping force and enhanced durability, this simple fix effectively prevents costly engine damage. A small price to pay to keep your MKIII Supra running smoothly on the road or the track. So don’t wait for head gasket failure to occur—take proactive steps to safeguard your Supra’s performance.