The Humble History of the Crash Test Dummy

From the public service announcements released by the National Highway Traffic Safety Administration (NHTSA) in the ’80s to the line of action figures produced in the ’90s by Tyco Toys, we’ve always been aware of crash test dummies.

Most of us have an idea of their purpose. They are used in safety tests to ensure that when a given car is crashed or hit, from any angle, it has optimal protective measures in place to protect its passengers.

Crash test dummy history and evolution

The first crash test dummies were actually cadavers. Their use showed how the injuries that resulted from a crash affected real human bodies. The cadavers weren’t always the standard shape needed though and during testing, they didn’t respond as living people would. There were brief forays into testing with live people and animals. Neither produced highly useful results and presented ethical dilemmas.

It wasn’t until 1949 that crash test dummies were first developed. The first dummies created served for testing aircraft ejection seats for the U.S. Air Force. Sierra Sam was the first crash test dummy, fixed to propelled sleds on rails.

The same type of dummy was later used by the automotive industry to develop shoulder harnesses and lap seat belts. Sierra Sam was roughly the same size and weight as the average man of the time. He had articulated limbs but a rigid neck and spine. The latter two conditions hampered results. When they tried to measure the movement of his head due to acceleration, it didn’t yield an accurate reaction.

Until the mid-1960s, the aviation industry, the military, and the space program led to the development of the dummies. But automobile fatalities were on the rise. Restraint systems needed improvement to better protect passenger abdomens, pelvis, spine, and rib cage areas.

The need for variety

By 1970, concerns rose because the adult-size male dummies didn’t give the data needed on what happened to smaller child and female physiques in crashes. Restraint systems designed to protect the adult male dummies were actually causing injuries to smaller passengers, especially children.

That year a larger male dummy, named Sierra Stan, and a female model named Sierra Susie came along. The same year saw them joined by Sierra Sammy, a dummy the size of a six-year-old child, and Sierra Toddler who was the size of a three-year-old. They didn’t get the weight distribution right for those first kid dummies but it was forward progress.

Crash test dummies continued to develop leading up to our current time, becoming more and more sophisticated. They were also adapted as the automobile industry advanced. 1997 was a year that saw large upgrades to automotive dummies as airbags became mandatory.

Today’s crash test dummy

Today’s crash test dummies must meet the requirements of the NHTSA. Manufacturer designs aren’t used. Dummy manufacturers receive construction specifications directly from the NHTSA. It’s a complex process that’s limited to clients like automakers, dummy manufacturers, and government agencies. Dummy manufacturers do get design input for changes based on data submitted to the NHTSA from testing.

Only a small number of companies in the world have the authorization to make dummies that must meet a high set of standards. There are no generic or mid-grade crash test dummies. Quality control involves an extremely thorough set of tests and measurements to ensure every detail meets the required specifications.

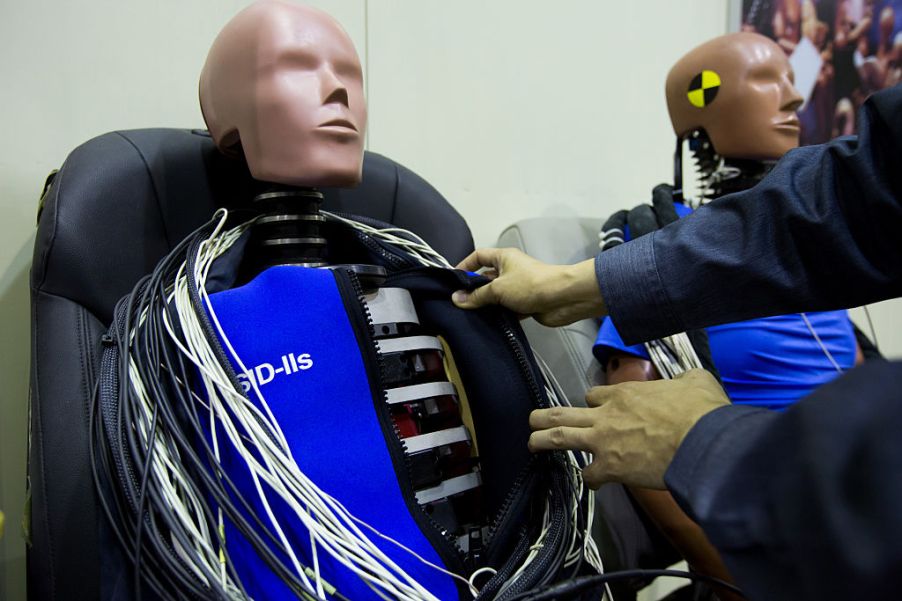

Current dummies are intricate in makeup. Their base uses parts made of aluminum, steel, or bronze often with metal plating. Delrin, polyurethane and urethane foam, and vinyl are just some of the plastics used. They are typically clothed for realism. Only specific vendors provide clothing, paint, and adhesives used to identify critical measurement points on the models.

The dummies undergo rigorous testing appropriate for their physique to ensure effectiveness. They undergo tests like calibration of knees, neck, skull, and more. They conduct head drop tests along with chest impact testing. Dummies receive certifications that stay with them to verify the testing it’s undergone. Certifications also help in future rebuilding, recalibration and retrofitting.

Also, as people change in size and shape, crash test dummies change accordingly.

Today’s dummies can cost up to $750,000 and contain as many as 80 or more specialized sensors. The more sophisticated models can save and send up to 10,000 data bits each second.

Crash test dummies can save lives

The dummies give their lives to enable automakers to make the safest vehicles possible. Strapped into a car that’s run into a wall at 40 miles per hour often leave both the car and dummy destroyed.

But dummy’s sensors provide a wealth of information that reveals how he did through the collision. The data reveals which parts of the body sustained injuries. The data tells how hard and fast the dummy hit the steering wheel with both his head and body. It also shows how effective both the airbags and the seatbelts were in doing their jobs.

One vital key to success is that the models must match the average passenger’s physique for their gender. Recent research conducted by the University of Virginia indicates that many female crash test dummies only weigh 110 lbs but the average woman weighs 170 lbs. The discrepancy may be contributing to a higher number of automotive female fatalities.

Dummies and cars endure test crashes of all kinds devised by automakers. Their goal is the dramatic reduction of fatalities in traffic accidents of all types by creating safer vehicles. With the continued help of crash test dummies and those who work hard to improve them, they hope to spare more limbs and lives. We owe a lot of thanks to these so-called “dummies”.