Video Revealed: Was NASCAR Next-Gen Crash Simulation Test Dummy ‘Killed’?

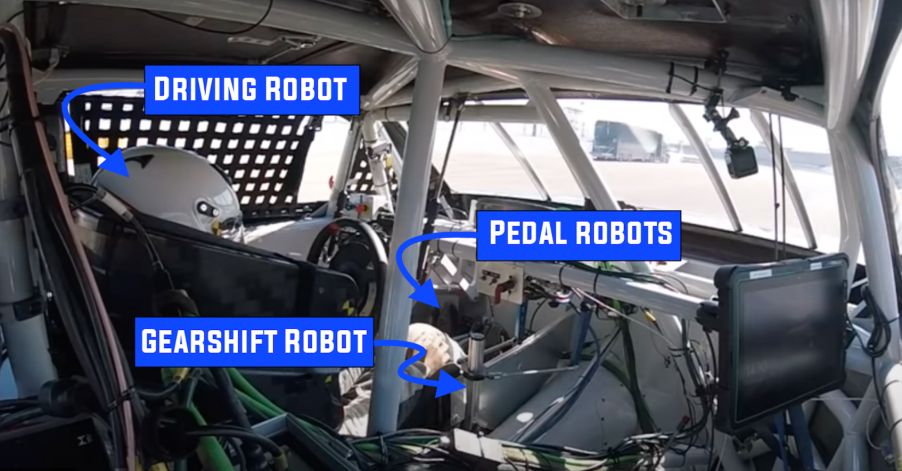

Back in 2021, after developing its Next-Gen racecar, NASCAR performed a crash test to further test-case what was the future of its Cup racing series. Testing was chosen to take place at Talladega Speedway in Alabama. In place of a real driver, a crash test dummy simulated the real deal. It was the same as those used for passenger car testing by the NHTSA. Three computer-controlled robots were inside the Next-Gen racecar. But after testing, rumors circulated that the damage to the dummies indicated the crash would have killed a human driver.

Here’s the NASCAR Next-Gen crash test

NASCAR performed over 5,000 Ansys crash simulations on the computer. But it never performed an actual crash test of a real racecar. After this real-world test, NASCAR made last-minute changes, which fuelled those killed-driver rumors. But NASCAR has never released the video of the crash test. That is, until now.

AB Dynamics supplied the robotic system, and the U.K.-based company programmed the robots. The plan was for the car to go to 130 mph, then crash into a specific point marked on a SAFER (Steel and Foam Energy Reduction) barrier. The crash would hit the barrier at a 24-degree angle.

Three robots took the place of one human. One controlled steering, one shifting, and one squeezed the throttle. To control the route the car would take, AB Dynamics used path-following software. The software pre-records information and GPS data. The software is precise-enough to hit the barrier point to within 2cm, at 130.015 mph, and plus or minus one to achieve the 24-degree angle.

What controlled the NASCAR crash-test dummy?

The crash dummy made no contact with the robotic equipment. “Our robots are largely used for the development of passenger and commercial vehicles and are regularly used for durability, misuse, and driver assistance system testing,” said AB Dynamics development manager Craig Hoyt. “This is one of the highest speed crash tests we have ever conducted, and the robots only suffered minor damage. It really is a testament to the safety of the vehicle, the barriers, and the ruggedness of our products.”

And of the Next-Gen car. “There is no better data than replicating crash tests in a real environment and our robots enable us to do that accurately and repeatedly,” says Hoyt. Based on the analysis of the crash, NASCAR implemented changes to the Next-Generation racecar. Removing some stiffness from the front and rear frame structures allowed for better energy absorption.

“This is a truly innovative way to test the safety of vehicles in motorsport,” John Patalak, NASCAR’s managing director of safety engineering, told PMW. “The data we obtained from the test was extremely important and was not possible to get from any crash test facilities at the time. The test provided valuable information for correlation with our computer crash simulations. It confirmed that the predicted vehicle impact performance from the simulation was duplicated in this real-world crash test.”