Would Cummins’ 1,000 Horsepower Military-Spec Diesel Engine Fit In Your Pickup Truck?

Something is brewing at Cummins: a 1,000-horsepower beast of a diesel engine specially ordered by the U.S. Military. This engine has just four cylinders but eight opposed pistons, and it is almost a perfect square. I know the question I’m asking is: Could I put one in my pickup truck? Here’s what swapping in a 1,000-horsepower opposed-piston Cummins would take–and why you likely wouldn’t want to.

Cummins is building a square engine

The inline six-cylinder engines Cummins builds for Ram trucks are tall, long, and narrow. But the company builds a very different engine for the military. Both the Army’s Bradley fighting vehicle and the M109A7 Howitzer leverage a 14.8-liter, 750-horsepower turbodiesel V8 built by Cummins.

But as the military designs its next generation of armored vehicles, it will need an even higher output engine. And in a confined, armored vehicle, the engine must take up as little space as possible. So Cummins partnered with Achates Power (pronounced Ah-kay-tees) to engineer a compact and powerful diesel using opposed-piston technology. The resulting powerplant won the Army’s $87 million “Advanced Combat Engine” contract.

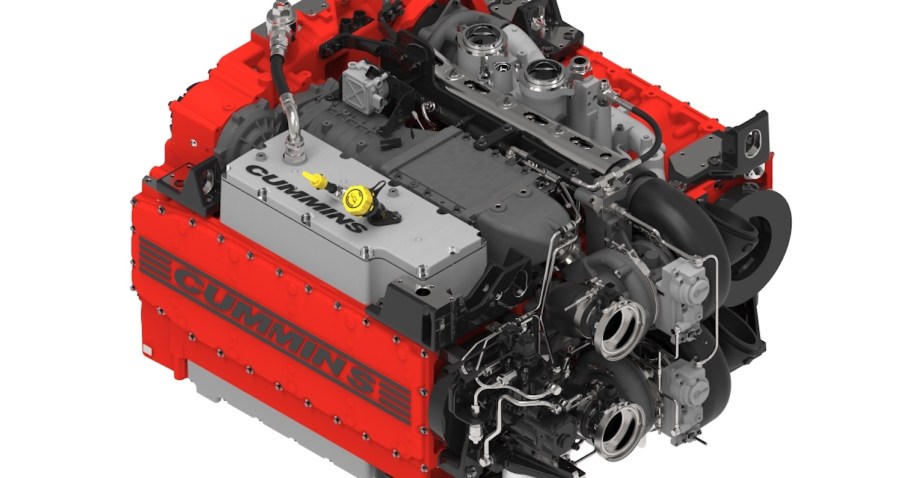

According to Cummins, the ACE will have a 31-inch long block. But with engine peripherals, it will be 48 inches long overall. It will be 43-inches wide and 23-inches tall. So, this square engine will be just under four feet by four feet and two feet high.

The ACE will be significantly wider than most modern engines–and wider than many engine bays. But it is still narrower than the front axle of a full-size truck, so if you were willing to reshape your fenders, you might be able to swap this 1,000-horsepower Cummins into your Ram. But considering its 3,500-pound weight, you probably won’t want to try and run it in a pickup.

How do opposed-piston engines work?

Just like their name implies, opposed-piston engines have two pistons in each cylinder. These pistons come together to create compression. The combustion cycle forces them back apart and rotates their separate driveshafts. While simple in theory, opposed-piston engines present some complex problems.

Early opposed-piston engines powered ships in the 1920s. They have also been used in large airplanes and even submarines. They can be more efficient than regular engines because they can capture more of the heat and pressure generated by the combustion cycle.

Opposed piston engines require some manner of gearing to connect their two crankshafts. Their builders must also invent some intake and exhaust valves that can work reliably in the middle of each combustion chamber. These complexities have made it difficult to build small opposed piston engines.

Since 2004, Achates Power has worked hard on these engineering challenges. Because an opposed piston engine has no valvetrain, it must be a two-stroke engine. One of Achates’ main hurdles was passing modern emissions standards. Some of its engines control airflow with both a turbocharger system and a supercharger system. This is an innovation that Cummins has adopted for the ACE engine. This certainly contributes to the opposed-piston Cummins’ enormous weight.

Is there a 1,000-horsepower Cummins 6BT?

Cummins has always designed its engines to optimize torque. But engine tuners have certainly built up 1,000 horsepower Cummins 6BTs to power Ram trucks.

If you are dreaming of a 1,000-horsepower diesel Ram, a built 6BT is a much simpler solution than trying to find and swap in the opposed-piston Cummins when that military-spec engine comes out.

Next, meet the 5,000+ horsepower Cummins QSK95, or see a 1,000-horsepower Cummins 6BT build in the video below: